Features

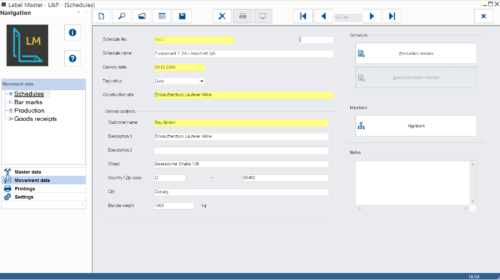

LabelMaster is a program for the planning, management and control of working processes in rebar shops and precast company. It enables the management of master data of the reinforcement industry as well as the creation of schedules and steel lists. On the basis of master data new schedules can be created respectively existing schedules can be processed. Steel lists, tags and possibly cutting lists can be printed for the schedules. Then the entered bar marks can be transferred directly to the machines.

The programme is structured modularly and thus an optimal adaption to customer’s requirements is possible.

Modules

Features:

- Machinery: Management of machines, optimization parameters and stock lengths

- Production lines: Join of machines to logical production lines

- Shape codes: Creation respectively processing of shape codes

- Steel grades: Management of steel grades and corresponding diameters

- Schedules: Creation of schedules with delivery date, delivery address and so on

- Steel bar marks: simple entry of steel bar marks with graphical creation of the shape dimensions

- Steel list: Printing of a steel list with graphical output of the shape

- Tags: Printing of tags with graphical output of the shape and PDF-barcode for offline downloading of the machines

- Manual allocation: Manual allocation of bar marks to other machines after creation of bar marks

- Language support: Several languages are supported

With the technical module you have the possibility to use a bar cutting optimization. When using the optimization the personnel expenditure on the machine can be reduced so that for the same working expenditure higher machine utilization and thus higher productivity will be reached. Another advantage of the optimization is the reduction of scrap and offcuts resulting in lower material cost. The optimization can be made schedule or diameter related. A schedule related optimization enables the fast production of a schedule whereas a diameter related optimization of several schedules enables minimum scrap and offcuts. The result of the optimization is a cutting list with a PDF-barcode. With this PDF-barcode the data for each cutting cycle can be transferred to the machine. On the cutting list also a summary of the used stock lengths will be shown where you can see how many of the corresponding stock lengths have been used and what is about scrap and offcuts of each stock length.

Offline-Downloading: Via PDF-barcode on the tag enabling an offline downloading of the machines. By means of reading the barcode there are no entry times on the machine and possible entry errors do not arise. Following you will see the printing of tags.

Goods receipts: incoming material will be registered together with the Cast numbers of the single bundles

Bundle tags: for each single raw material bundle a bundle tag with a barcode can be printed

Allocation of Cast numbers: the produced items are allocated to the Cast number of the raw material bundle they are made from either after or during the production

Certificates: the certificates can be assigned to the raw material bundles and printed automatically with the Steel list

LabelMaster can be used on all workstations of the computer network

System requirements

State: 1st of February 2018

Workstation – Minimum Requirements

- Intel Dual-Core, 4 GB RAM

- min. 3 GB free HDD space

- Microsoft Windows 7 Professional

- Microsoft .NET-Framework 4.0 or higher

- Graphic card with a min. resolution of 1024 x 768 pixels

- Mouse

- For further software additional HDD space and RAM is required

Workstation – Recommendation

- Intel Core i5, 3 GHz, 8 GB RAM

- min. 10 GB free HDD space

- Microsoft Windows 10 Professional

- Microsoft .NET-Framework 4.0 or higher

- Graphic card with a min. resolution of 1280 x 1024 pixels

- Mouse

- For further software additional HDD space and RAM is required

Printer

- 1 piece, with compatible Windows driver

- Available within the network