Software for structural engineers, construction companies and rebar shops - Digitise together

Company profile 2026

WIFI Scanner Pokini FS5B TAB with LTE & GPS

Manufacturer from Finland – The new scanners are not only a great step forward in terms of appearance, but also functionally. The combination with our new apps offers completely new possibilities due to the large display and handling.

Simplify your internal processes and increase your productivity.

+++ News about LENNERTS & PARTNER +++

Reinforcing steel processing fully automated and optimum production and logistics.

The new BVBS guideline 3.0 was published beginning of September.

We are looking for new staff!

Support

Join us at the

Hall 17, Stand 17D44

from 13 to 17 April 2026

Düsseldorf

Features of our software

Maintenance of master data

Order processing

Production

Machine downloading

Delivery control via scanning

Invoicing

Stock management

Purchasing

Interfaces to external ERP system

Bar cutting optimization

Electronic document dispatch

Digital import of schedules

LP-System

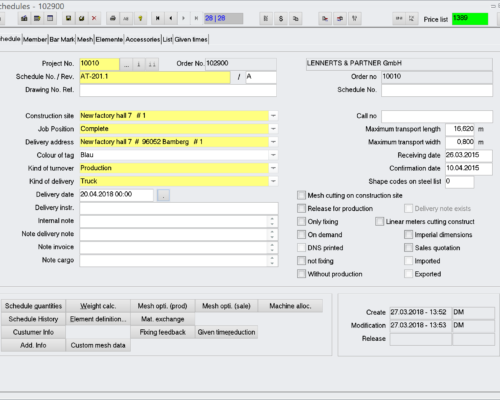

LP-SYSTEM has been developed to cover all processes of a rebar shop. Thus the software solution supports planning and steering as well as the control of the whole procedure. Simultaneously, the system can be adapted exactly to your needs by its modular design and flexible settings and parameters.

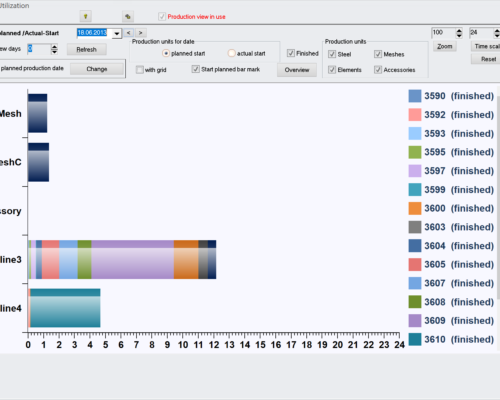

LP-Prodplan

LP-PRODPLAN – Adding to the functionality of the commercial part, a comprehensive production planning module is available. Here the existing machines together with their attributes can be entered and combined to production lines considering the conditions in the shop floor. Based on this data and additionally on your individual priorities an automatic machine allocation validates the consistancy and plausibility of each machine and assigns the corresponding production line to each single bar marks. A manual reallocation of the assigned bar marks is also available like an overview of the machine allocation and work load per machine.

LP-LabelMaster

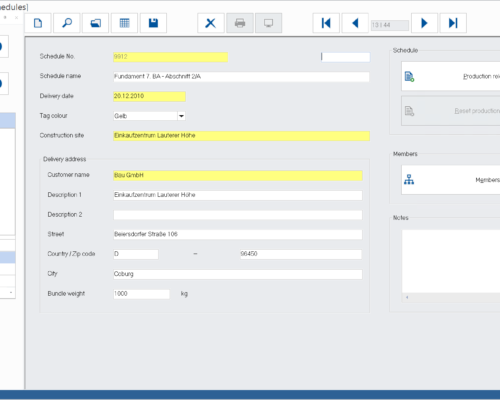

LP-LabelMaster is a program for the planning, management and control of working processes in rebar shops and precast company. It enables the management of master data of the reinforcement industry as well as the creation of schedules and steel lists. On the basis of master data new schedules can be created respectively existing schedules can be processed. Steel lists, tags and possibly cutting lists can be printed for the schedules. Then the entered bar marks can be transferred directly to the machines.